How OI’s Innovation Works

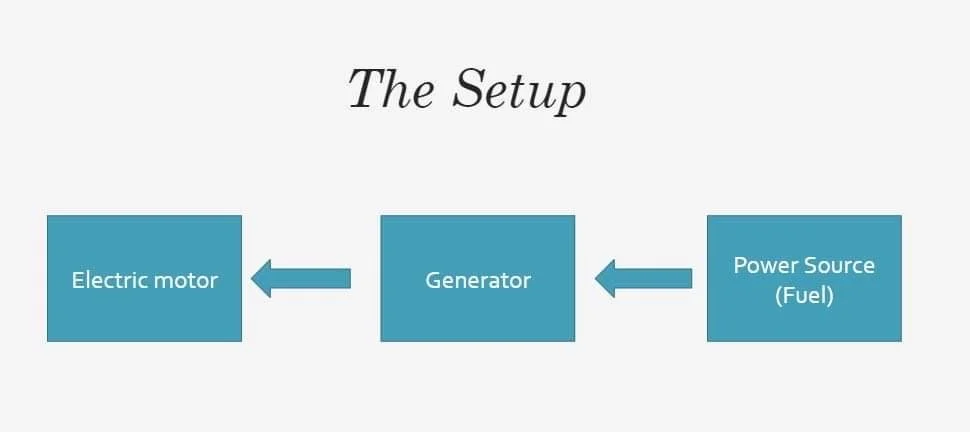

Our engines have two components, the power unit and the propulsion unit. The power unit works by using a power turbine to convert the energy from fuel into “shaft work” or in other words a turbo-shaft engine as the focus of the turbine is to generate power not thrust. The power generated from the turbines will then be harvested by a generator to power to power both the propulsion unit and the needs of the cabin. The propulsion unit consists of an electric motor that open inductions have developed. As a result each components can be individually maximized for optimal performance.

In short, our hybrid engines work more like a turbo-prop engine with the performance of a turbo-fan engine. Due, the smaller size in turbines used in power generation and the compact and light motor design Open Inductions has Developed. The hybrid engine can be aligned and positioned in a way that it has the potential to be directly fitted in the engine nacelle of current commercial aircrafts. With this concept higher bypass-ratios can be achieved resulting in a more efficient engine. Lastly, due to the decoupling between the power unit and propulsion unit an fuel savings of 50% can be achieved. The 50% fuel savings was found by performing tests on our prototype the Electric Mega Fan (EMF) 600-OR series connected to an external generator.